-

Hotline : +84 981 282 028

- vyan.company@gmail.com

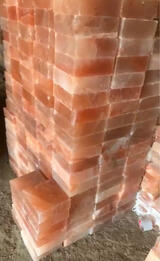

Hymalayan Pink Crystal Salt

Price:

ContactPeople are viewing this right now

Exploring The Pink Gold – Himalayan Salt Mining Process:

None of us can deny the health and wellness benefits of Himalayan pink salt from Pakistan. It is being used for various purposes including cooking, salt therapy, skincare products, and other spa treatments. This is due to the uniqueness of the Hymalayan Pink Crystal Salt crystal structure and its hand mining from the Pakistan.

Pakistan exports around 400,000 tons of Himalayan salt every year in the form of different salt products. Read along to find out some interesting facts about the Himalayan pink salt mining to appreciate the efforts of the laborers who bring nothing less than Hymalayan Pink Crystal Salt to your tables.

Extraction Of Himalayan Salt From Pakistan

Himalayan salt is only found in salt mines located in Pakistan. This salt comes from the world’s second-largest salt mine located in Khewra, Punjab. The area, known as the salt range, is present in the foothills of the Himalayas in Pakistan.

The geologists believe that the Himalayan pink salt mine was formed by the shifting of tectonic plates that trapped the inland sea around 250 million years ago. Later, the sea was dehydrated, leaving behind massive rocks of Himalayan salt.

Any form of Hymalayan Pink Crystal Salt you find in local stores around the world comes from Pakistan. The good news is that these salt deposits are sufficient to produce Himalayan salt for hundreds of years. Mining from these salt deposits is done by professional miners using different techniques.

Himalayan Salt Mining:

Many people say that it was Alexander the Great’s horses, who discovered these salt deposits. However, later, the Britishers were the ones who ramped up the salt mining process in the 1870s. They developed proper tunnels inside the mine to extract this precious rock salt. Then, one of the British mining engineers came up with an innovative idea to extend the tunnel system inside the mine, known as the “Room and Pillar.”

Interestingly, this architectural system is still in use because of its efficiency. The miners extract half of the mined salt in the room during the salt mining process, while the remaining 50 percent serves as the room’s pillar. This method not only ensures the safety of the mines but also helps in maintaining the structural integrity of the mountain ranges and salt chambers.

You’ll be surprised to know that 19 stories are inside the mine, out of which 11 are below the ground. The salt mine is around 730 meters deep in the mountains, while the total length of the tunnels is approximately 40 kilometers. Furthermore, the temperature inside the mine ranges between 10ºC to 20ºC degrees throughout the year.

The installation of the electric railway in the 1930s made it convenient to extract the salt rocks outside the mine. Additionally, it allowed the tourists to witness the extraction process.

Early Opening Of The Mine

The laborers and miners use explosives and dynamite just once to open the main entrance in the initial phase. First, they use the auger to drill by hand and then pack the gunpowder. Later, they ignite it using a protection fuse and blast out the salt.

This method has been in use for hundreds of years; however, its use is discouraged inside the mine as the toxins pose a severe health risk. Moreover, it’s necessary to keep the crystalline structure of the Himalayan salt intact.

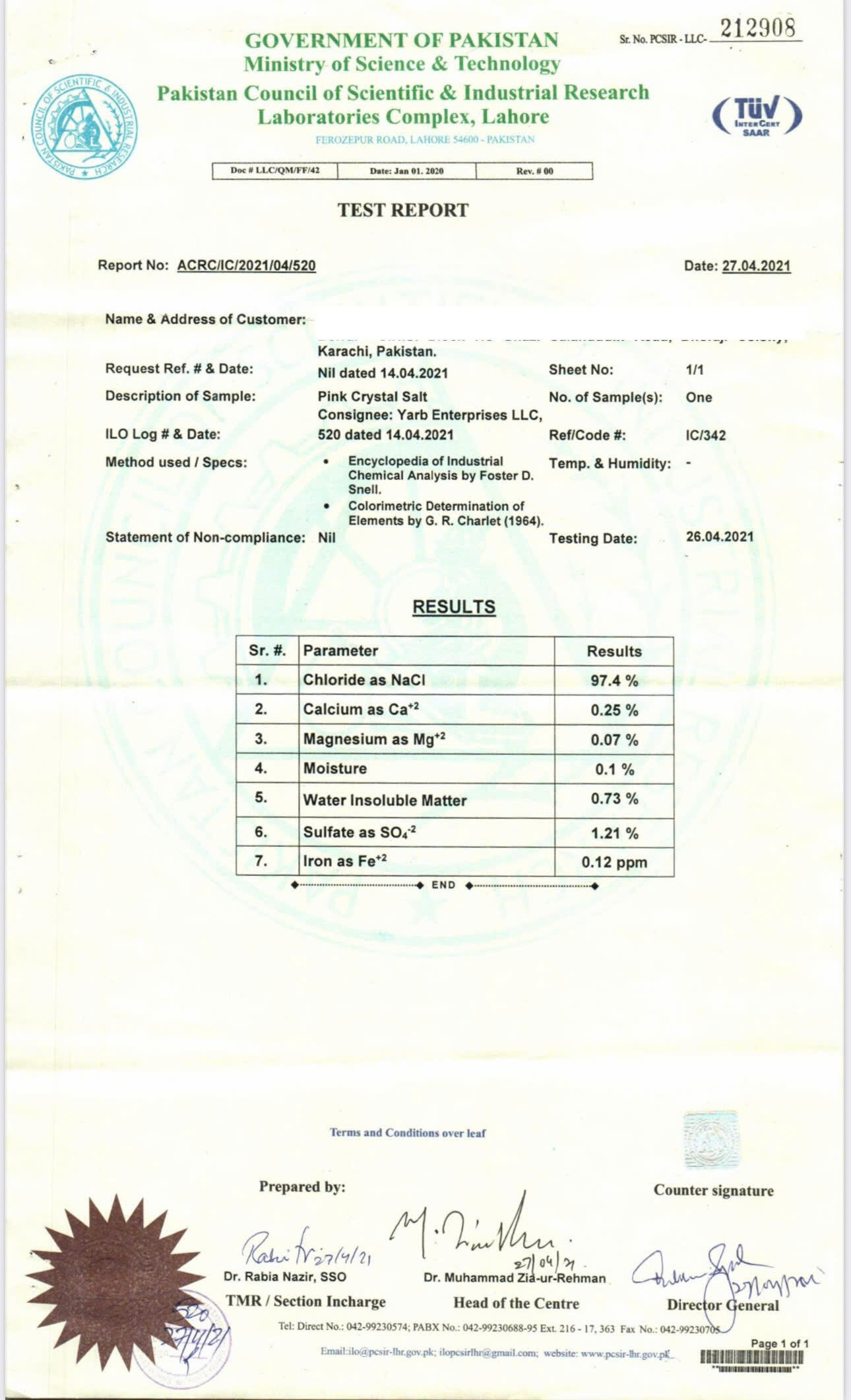

Here are some specifications for Pink Crystal Salt:

Chemical Composition: Primarily sodium chloride (NaCl), with purity levels around 97-99.86%.

Mineral Content: Contains trace minerals like calcium, magnesium, iron, and potassium.

Moisture Content: Typically ≤ 0.2%.

Grain Size: Varies from fine crystals (20-50 mesh) to extra coarse granules.

Water Insoluble Matter: ≤ 0.15%.

Shelf Life: Indefinite, as salt does not spoil or support bacterial growth.

Storage Conditions: Best stored in a dry, covered area with humidity below 75% to prevent caking.

Certifications: Often Kosher and Halal certified, and free from allergens or additives.

https://youtube.com/shorts/GE5fVvrpzbY?si=br603kslffKAJbhI