-

Hotline : +84 981 282 028

- vyan.company@gmail.com

-

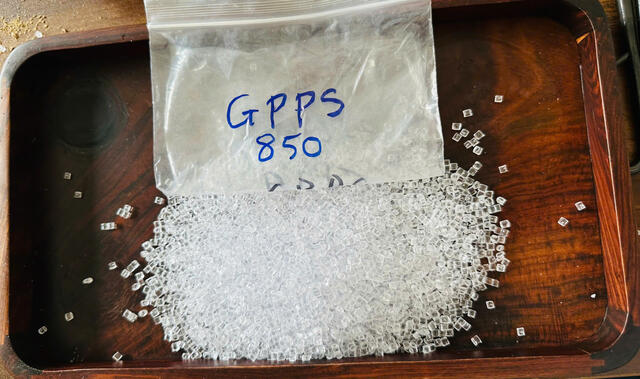

Primary Plastic Beads

Virgin plastic resin is a type of plastic produced directly from petroleum, unused, and free of impurities or additives. This high-purity plastic is typically white in its natural state and is widely used in various industries, including food packaging, medical equipment, electronic components, and household products. Characteristics of Virgin Plastic Resin - High Purity: Contains no additives or impurities, ensuring the best quality. - Elasticity and Durability: Offers good resistance to stress and minimal warping. - Safe and Environmentally Friendly: Does not emit toxic gases when burned, making it suitable for products requiring high safety standards.Price: Contact -

BITUMEN 60 - 70

Bitumen is a highly viscous binder commonly used in road construction and waterproofing materials. It has excellent heat resistance, melting when heated and solidifying when cooled. Additionally, bitumen is water-resistant, helping protect surfaces from moisture and weather effectsPrice: Contact -

Sulfur

Petroleum-derived sulfur is primarily recovered from oil refining and natural gas processing. It is an essential byproduct that helps reduce sulfur content in fuels to meet environmental standards. Production Process: - Hydrodesulfurization (HDS): Uses hydrogen and catalysts to remove sulfur from crude oil. - Claus Process: Converts hydrogen sulfide (H₂S) from natural gas into elemental sulfur. - Frasch Process: A mining technique that extracts sulfur from underground deposits using superheated water. Applications: - Sulfuric Acid Production – A vital raw material for the chemical industry. - Metallurgy – Used in ore processing and metal refining. - Rubber Industry – Essential for vulcanization, improving product durability. - Fertilizer Manufacturing – Particularly for sulfate-based fertilizers. Petroleum-derived sulfur plays a crucial role across multiple industries and is increasingly recovered to minimize environmental impact.Price: Contact